Avoid Tin Plated Parts The best strategy to prevent tin whisker induced failure of electronic hardware is to avoid using pure tin plating on any of the parts used in the construction of the electronic hardware such as lead finishes RF shields mounting hardware and electronic enclosures. NASA Advisory NA-044 October 23 1998.

Smf4l Series 400w Surface Mount Diodes Littelfuse Mouser

How Can RAF Electronic Hardware Help.

Matte tin finish electronic components. For electronic components only a matte of flow brightened finish shall be furnished. NASA Tin and Other Metal Whisker Homepage. Lead-Free Movement Electroplated and dip-coated finishes are applied to electronic components primarily to protect the base.

Most Hi-Rel OEMs have acceptance criteria that include a combination of Mitigation Practices Specific plating andor treatments used with the express purpose of. These are among the common finishes being considered in the electronics industry as replacements for Sn-Pb. 331 Thickness of Plating Unless otherwise specified the thickness of the plating except on electronic components shall not be less the 00003 inches and shall not be greater than 00005 inches on visible surfaces that can be touched by a 075 inch sphere.

Components with surface finishes of pure matte Sn Sn-3Cu and Sn alloyed with Bi in concentrations of 1 3 and 6 weight percent. The Matte tin has a larger grain size than Bright tin. Ad RAF is the Nations Leading Manufacturer of Electronic Connector Hardware.

When optimized for each application metallization and surface treatments enhance the reliability and functionality of electronic components. Today TIs lead-free products use NiPdAu or annealed matte tin Sn for leadframe type packages and TinSilverCopper SnAgCu for ball grid array BGA types of products. If the materials are so similar why is one dull in appearance and the other shiny.

8 Million Parts Online. Use of matte tin electroplating and annealing or fusing of the tin layer are inadequate. Ranging from parametric deviations to catastrophic short circuits tin and zinc whiskers may interfere with sensitive optical surfaces or the movement of micro-.

Matte tin finish for electronic components 2006. Tin-Lead is soft and very ductile and color can range from a matte gray to a very bright finish. By 2000 these products moved to a NickelPalladiumGold NiPdAu.

StanTek SST 3000 acid tin plating process produces a fine grained satin pure tin deposit. Same Day Shipping Order by 8pm CST. Matte tin is a tin film with lower internal stresses and larger grain sizes than so called bright tin and is therefore less prone to whisker formation.

Tin-Lead is soft and very ductile and color can range from a matte gray to a very bright finish. They likely reduce the incidence of nucleation or growth but do not provide an absolute guarantee of lack of whisker formation. Matte silver plate is used extensively for finishing electronic components where silvers mechanical properties of silver plate alone may not be enough and the design engineer feels that appearance may also be an important consideration.

A high speed satinmatte tin plating process for reel to reel applications. NASA Advisory NA-044A December 17 1998. The electronics industry is moving toward lead-free components which has caused difficulty at production test.

Matte tin Sn is a Pb-free finish also being proposed as a replacement for tinlead SnPb plating. This matte tin option will be available on all packages except for solder bump termination packages and hi-rel products. Compare Pricing Inventory and Datasheets for Millions of In-Stock Parts.

Matte and bright tin finishes are defined by the following. In particular bright tin finishes have been show to. Pure tin plating is prohibited as a final finish on EEE parts and associated hardware.

It is designed for rack and barrel plating of electronic components which may also require heat aging prior to. MSIs Tin-Lead plating conforms to MIL-P-81728A and offers excellent solderability and good corrosion resistance. A matte Tin-Lead finish is often used on electronic hardware when solderability is required.

Dull Matte Finish Bright Acid Tin. This investigation included metallographic examination and lead pull testing of aged and unaged joints. The device leads now have a matte tin finish causing increased contact resistance and reduced yields while requiring frequent cleaning of printed circuit boards and contactors.

Ad Compare and Save on Millions of Electronic Components Now. This will vary with the manufacturer and the specific component. For electronic components and connectors the plating is typically in the 150 micro-inch to 450 micro-inch thickness.

Devices with the matte-tin termination packages are indicated by an E3 suffix. Bright tin and matte solderable tin. Both deposits are electrolytically applied.

Bright tin plating has a high degree of luster and is generally preferred for electrical contact applications such as bus bars terminals and switching components that are not soldered to. Request Samples a Catalog a Quote Or Download CAD. Matte Tin Sn Tin has good wettabilitysolderability over a large range of substrates making it an excellent choice for lead leg or pin finish through tin plating.

Ad Over 800 Suppliers and 8 Million Parts. Ad Largest inventory of connectors passives emech from leading manufacturers. Supporting these industry trends require metal finishing materials that ensure excellent component performance in a variety of environments.

For example the lead-free version of part number Si4410BDY-T1 would be ordered as Si4410BDY-T1-E3. Parameter Matte Sn Bright Sn Carbon Content 0005-0050. Pure tin and zinc finishes can be susceptible to the spontaneous growth of single crystal structures known as tin or zinc whiskers which can cause electrical failures.

MSIs Tin-Lead plating conforms to MIL-P-81728A and offers excellent solderability and good corrosion resistance. Ductile Bright Finish ASTM B 545 SPECIFICATIONS Thickness Classes A - 00001 B - 00002 C - 000032 00004 for steel D - 00006 00008 for steel E - 00012 F - 000006 Purity 995 Underplate Thickness Nickel at 50µ thickness Lead Composition 705 by mass ADDITIONAL INFORMATION. Finish Type Alkaline Tin.

It has been designed for continuous connector and strip plating. A matte Tin-Lead finish is often used on electronic hardware when solderability is required. Tin plating services can be broken up into two primary categories.

Modern IC packaging methods have mitigated the tin whisker problems which previously hampered. Finish on mechanical parts where a common finish choice is zinc. The Sn or SnPb finish is plated after molding of the IC package.

Matte Tin and Tin Alloys. Components with matte-Sn-finished leads and as a control components with SnPb-finished leads are included in this study. 2 Overview Pure Tin and High Tin Content Alloy Pb-Free Finishes are a reliability risk for electronic products due to potential for tin whisker growth Concerns are more than just short circuits.

By 1989 TI introduced the NickelPalladium NiPd finish as a lead-free alternative to the IC market.

Components Corp Tp 104 01 05 Test Point Green Ibs Electronics

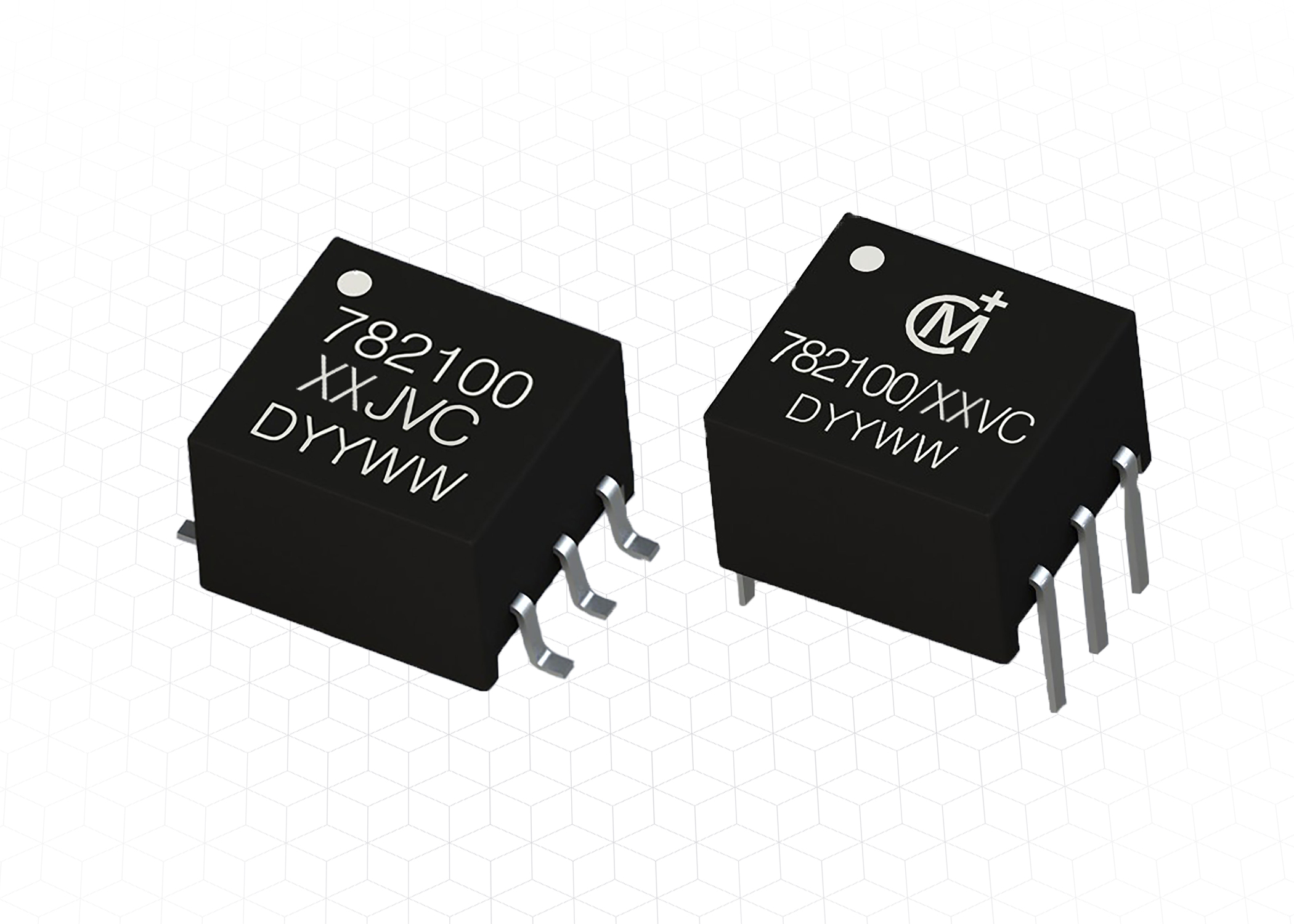

Murata S New Psemi Approved Transformers Save Time And Cost Murata Power Solutions

Tidak ada komentar